Common Raw Materials For Watch Display Stands

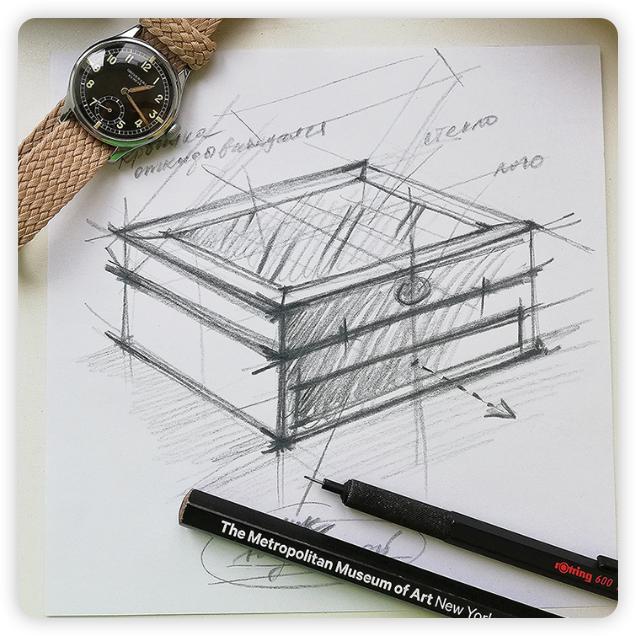

We usually choose MDF as wood material for wooden watch display stand.

What is MDF?

It is Medium Density Fibreboard. MDF is a man-made board made by mechanically separating and chemically treating wood or plant fibers, adding adhesives and waterproofing agents, and then molding under high temperature and high pressure. It is an ideal man-made board for making wooden display stand. MDF can be produced from a few millimeters to tens of millimeters thick, can replace any thickness of wood, square timber, and has good mechanical processing performance, sawing, drilling, slotting, tenoning, sanding and engraving , The edge of the plate can be processed according to any shape, and the surface is smooth after processing.

In general, wooden display stand will be covered with surface finishing after wood cutting process. Lacquered is one of mostly used, especially for watch display stand.

There are mainly two type lacquer, matte lacquer and glossy lacquer. Matte lacquer and shiny lacquer differ mainly in terms of gloss, degree of reflection, visual impact, etc.

Acrylic, also known as PMMA or plexiglass, is used for wooden watch display stand as background picture frame. Although there are many color acrylic, but mostly chosen is transparent acrylic, because promotion picture need to be shown on the display.

Glossy Lacquer Watch Display

Matte Lacquer Watch Display

Why Transparent Acrylic Is Chosen To Be Used As Background Picture Frame For Wooden Watch Display?

•The light transmittance of the acrylic board is very good, with crystal-like transparency, and the light transmittance is above 92%, so many people use the acrylic board as the material of the brand LOGO, which requires less light intensity, so it is more energy-saving.

•Acrylic board has very good weather resistance and acid and alkali resistance, so it can be used outdoors. And it will not be yellowed or hydrolyzed due to prolonged exposure to the sun and rain.

•The impact resistance of acrylic board is very good, which is sixteen times that of ordinary glass, so it is safer to use and has a longer service life.

•The high recyclability of acrylic is recognized by the growing awareness of environmental protection.

•Easy to maintain, easy to clean, and acrylic can be cleaned by rainwater naturally, or just scrub with soap and soft cloth.

Common Raw Materials For Jewelry Display Stands

We usually choose MDF as wood material for wooden watch display stand.

What is MDF?

It is Medium Density Fibreboard. MDF is a man-made board made by mechanically separating and chemically treating wood or plant fibers, adding adhesives and waterproofing agents, and then molding under high temperature and high pressure. It is an ideal man-made board for making wooden display stand. MDF can be produced from a few millimeters to tens of millimeters thick, can replace any thickness of wood, square timber, and has good mechanical processing performance, sawing, drilling, slotting, tenoning, sanding and engraving , The edge of the plate can be processed according to any shape, and the surface is smooth after processing.

A. Lacquer

In general, wooden display stand will be covered with surface finishing after wood cutting process. Lacquered is one of mostly used, especially for watch display stand.

There are mainly two type lacquer, matte lacquer and glossy lacquer. Matte lacquer and shiny lacquer differ mainly in terms of gloss, degree of reflection, visual impact, etc.

B. Fabric Material

Except for being lacquered, jewelry display also can be covered with PU leather, velvet and microfiber. Besides, fabric will be used widely in jewelry display stand because soft fabric can protect jewelry well, even they fall down on the display, soft fabric can prevent jewelry from damage and scratches.

Advantage of PU Leather, Velvet and Microfiber

PU Leather

PU leather is a man-made synthetic material with a natural texture and is very strong and durable. It is closer to leather fabrics. It does not use plasticizers to achieve soft properties, so it will not become hard and brittle. At the same time, it has the advantages of rich colors and various patterns, and its price is cheaper than leather fabrics, so it is welcomed by consumers. The advantages of PU leather are that it is lighter in weight, waterproof, not easy to swell or deform after absorbing water, environmentally friendly, has a lighter smell, is easy to take care of, is cheap, and can press more patterns on the surface.

Velvet

The velvet is made of polyester fiber, and the fabric made by acupuncture is soft and skin-friendly and it is good for jewelry display, soft touching and can protect the jewelry from scratches. The velvet is light and clean in appearance, and has good air permeability. The texture of velvet is soft, light and transparent, smooth and elastic to the touch, after high temperature shrinkage treatment, it is not easy to deform and wrinkle. In addition, velvet has good physical properties, high fiber strength, wear resistance and durability.

Microfiber

Microfiber is superfine fiber, which belongs to a kind of newly developed high-grade leather in synthetic leather. It has no pores and neat lines. Because of its advantages of wear resistance, cold resistance, breathability, aging resistance, soft texture and beautiful appearance, it has become an ideal material to replace natural leather. Microfiber has moderate elongation, high tear strength and peel strength (abrasion resistance, tear strength, high tensile strength). There is no pollution from production to use, and the environmental protection performance is superior.

Common Raw Materials For Wooden Box

We usually choose MDF as wood material for wooden watch display stand.

What is MDF?

It is Medium Density Fibreboard. MDF is a man-made board made by mechanically separating and chemically treating wood or plant fibers, adding adhesives and waterproofing agents, and then molding under high temperature and high pressure. It is an ideal man-made board for making wooden display stand. MDF can be produced from a few millimeters to tens of millimeters thick, can replace any thickness of wood, square timber, and has good mechanical processing performance, sawing, drilling, slotting, tenoning, sanding and engraving , The edge of the plate can be processed according to any shape, and the surface is smooth after processing.

Wooden box need to be covered with surface finishing after wood material being cut. Lacquer surface is mostly chosen by customers for wooden box. There are two kinds of lacquer, matte lacquer and glossy lacquer (also called shiny lacquer). Glossy lacquer wooden box looks more luxury than matte lacquer wooden box, but cost is also higher than the matte lacquer one.

There are several options for inner lining in wooden box, however, mostly used are PU leather and velvet. To choose which one? It all depends on customers’ favour because there is no very big price difference between them. Below is characteristic for them.

Glossy Lacquer Wooden Watch Box

Matte Lacquer Wooden Watch Box

Velvet Inner Lining

PU Leather Inner Lining

Common Raw Materials For Leather Box

Generally speaking, there are mainly two material used for leather box as box body. One is MDF, another one is plastic mould. Mostly used is plastic mould because of its convenience and low cost.

A. MDF Box Body

B. Plastic Box Body

Plastic mould is made of plastic under huge press in the machine. A box mould will be made after box shape, box size thickness and box size confirmed, then raw material plastic liquid will be pour in the mould, after waiting for a while time, a box mould is finished.

•PU leather is very popular among packaging designers and home decor as it looks very chic and expensive while being a very durable material. PU leather is a very popular material for packaging box and gift box, especially for men's jewelry boxes as it is thought to give it a more manly, rugged look, while fabrics like satin or velvet or materials like glass give women's jewelry Box with an elegant and sophisticated feel.

•Leather has both the required flexibility and the durability customers want, so it is often chosen as the surface material of the packaging box. In recent years, consumers have become more and more interested in artificial leather, because genuine leather has extremely high environmental protection and cost.

•However, this is not the only reason why consumers choose artificial leather products. There are also the following reasons. First of all, the size of artificial leather can exceed the size of most animals, which means that people can have more choices. Also, since it is produced synthetically, it can be made into a matte or stronger material as desired. In addition to this, faux leather does not soften and age like real leather, which means it can be used for a longer period of time while maintaining its original properties.

•If you have box size requirement, MDF box body is better, as MDF can be cut into all size as long as you want. Plastic box size only can be chosen from sample box book. If you want your own size, then you need to customize a metal mould and moulding cost is very expensive.

•If you want low cost box body, then you can choose plastic box. Plastic box factory always produce a huge quantity one time for each box size and keep in their warehouse, production cost is much lower than small quantity production and customized order. When we purchase plastic box in stock, cost is low.

•If you want a light weight box, plastic box is a very good choice for you. With same size, MDF box is heavier than plastic box. Plastic box is not only can lower purchase cost, but also can save shipping cost with lighter weight.

Common Raw Materials For Paper Box

Many paper material can be used for paper box making, but these material usually are used as paper box body material, cardboard, coated paper and corrugated paper.

A. Cardboard

B. Coated Paper

C. Corrugated Paper

A. Art Paper

B. Specialty Paper

Learn More About Body Materials Of Paper Box

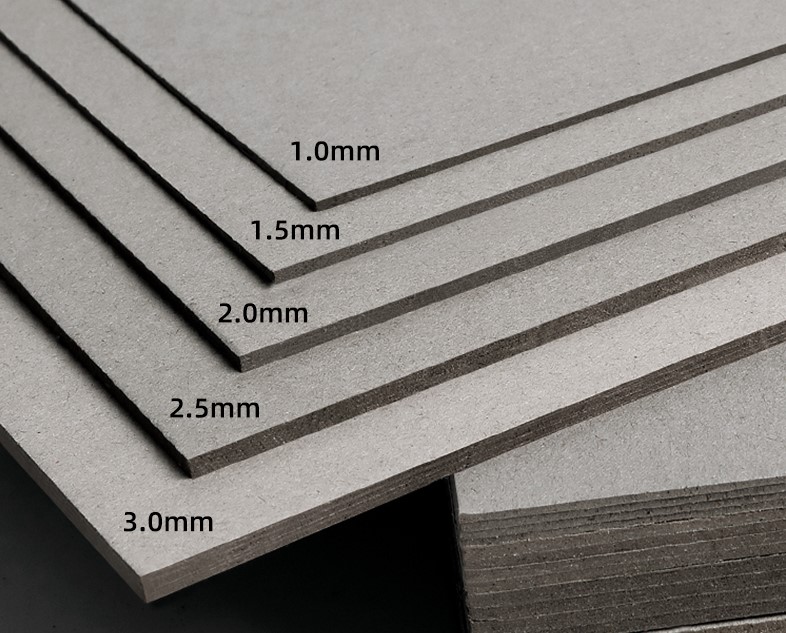

Cardboard

Cardboard paper is a kind of cardboard made of recycled waste paper, which is an environmentally friendly packaging material. The paper surface is thin, moderately smooth, with good stiffness, straight, sufficient thickness, tough and not easily deformed. Among all papers, gray cardboard is the most widely used and can be seen everywhere in life. Mainly used for packaging boxes, advertising boards, folders, photo frame backboards, luggage, hardcover books, storage boxes, samples, lining boards, puzzles, partitions, etc. The price of gray cardboard is the cheapest, and it is deeply loved by packaging and printing factories. Therefore, more and more products are produced with gray cardboard to save costs.

Coated Paper

•Coated paper, also known as printing coated paper, is a high-grade printing paper made of base paper coated with white paint. Coated paper is coated with a layer of white paint on the surface of base paper and processed by super calendering. The surface of the paper is smooth, the whiteness is high, the paper fibers are evenly distributed, the thickness is uniform, the stretchability is small, it has good elasticity, strong water resistance and tensile performance, and the ink absorption and ink retention performance is very good. It is mainly used for offset printing and gravure fine mesh printing, such as high-end picture albums, calendars, illustrations in books and periodicals, paper box surface paper or box body material, etc.

•Coated paper is divided into single-sided coated paper, double-sided coated paper, matte coated paper, and cloth-pattern coated paper. According to the quality, it is divided into three grades: A, B, and C.

•The grams of coated paper are 70, 80, 105, 128, 157, 180, 200, 230, 250, 300, 400, 450 grams, etc.

•Advantages: the color is very bright, the paper is very color-absorbing, and the color reproduction is high. It can be covered with a film. After the film is covered, it will feel more hand-feeling. The original material of the paper is very smooth and textured.

•Disadvantages: The handwriting is not easy to dry, because it is too smooth, so things written with pens and fountain pens (gel pens) are easily erased. Compared with the paper of the same gram, the hardness is in the middle, not too hard, and the price is low.

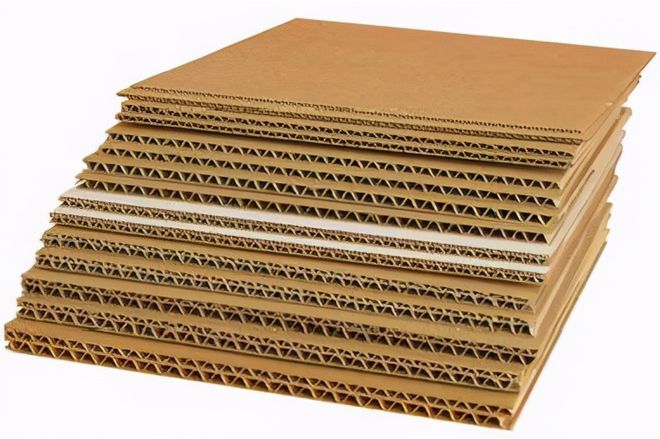

Corrugated Paper

•Corrugated paper is a plate made of a piece of smooth kraft paper and a piece of corrugated corrugated paper formed by processing a corrugated stick. It is generally divided into two types: single corrugated cardboard and double corrugated cardboard.

•In the past, part or even all of kraft paper was made of wood pulp, about 200 to 250g. Waste paper, and the thickness is much thinner than before, usually 120 to 160g, and occasionally 200g paper is used. As for the paper core, it is all recycled waste paper, and its thickness has also been changed from 130 to 160g in the past to 100 to 140g.

•The corrugated of corrugated cardboard is like a connected arched door, juxtaposed with each other in a row, supporting each other, forming a triangular structure with good mechanical strength. It can also bear a certain pressure from the plane, and is elastic and has a good cushioning effect. It can be made into pads or containers of various shapes and sizes according to needs, and it is simpler and faster than plastic cushioning materials. It is less affected by temperature, has good shading properties, does not deteriorate under light, and is generally less affected by humidity, but it is not suitable for long-term use in an environment with high humidity, which will affect its strength

•According to the corrugated size, it is divided into five types: A, B, C, E, and F. The larger the corrugated cardboard pit diameter, the stronger its rigidity. The toughness of the cardboard comes from the core paper layer, without thick and hard fillers, which can reduce the weight of the cardboard and its cost. A-type corrugated and B-type corrugated are generally used as outer packaging boxes for transportation, and beer boxes are generally made of B-shaped corrugated. E corrugated is mostly used as a single-piece packaging box with certain aesthetic requirements and suitable weight content. F-type corrugated and G-shaped corrugated are collectively called micro-corrugated. Disposable packaging containers, or used as packaging boxes for microelectronic products such as digital cameras, portable stereos, and refrigerated goods.

Surface Paper Material

Art Paper

•Art paper, also called double-coated paper, refers to double-sided coated paper, which is a kind of coated paper, which is double-sided coated. Both sides of art paper have very good smoothness.

•Whether you choose single coated paper or double coated paper to make paper box depends on whether you print on both sides. If both sides are printed and the effect needs to be very good, then double coated paper must be selected.

•Coated paper is divided into single-coated paper and double-coated paper to meet various printing needs. Single coated paper can only be printed on one side. It is often used to make red envelopes, portable paper bags, clothing bags, exhibition bags, packaging boxes and so on.

• In the same way, double coated paper can be printed on both sides. It is often used on the cover and inside pages of high-end books, business cards, brochures, desk calendars, etc. Usually the best way to distinguish these two kinds of paper is to see if it is double-sided printing, If it is not double-sided printed, then this is a single copper paper. Another way is to rely on hand touching. Both sides of the double coated paper are smooth, while the single copper paper is smooth on one side and not smooth on the other side. Of course, the smooth side is the printing side.

Specialty Paper

•Specialty paper is paper with special purpose and relatively small output. There are many kinds of special paper, which is a general term for various special-purpose papers or art papers, but now sellers refer to art papers such as embossed papers as special papers, mainly to simplify the confusion of nouns caused by the wide variety.

•Specialty paper is made of different fibers into paper with special functions by paper machine. For example, use synthetic fiber, synthetic pulp or mixed wood pulp and other raw materials alone, and modify or process different materials to endow paper with different functions and uses.

•Specialty paper is very normal and used popularly in packaging and printing industry. It is usually used for paper box, paper bag, name card, etc.

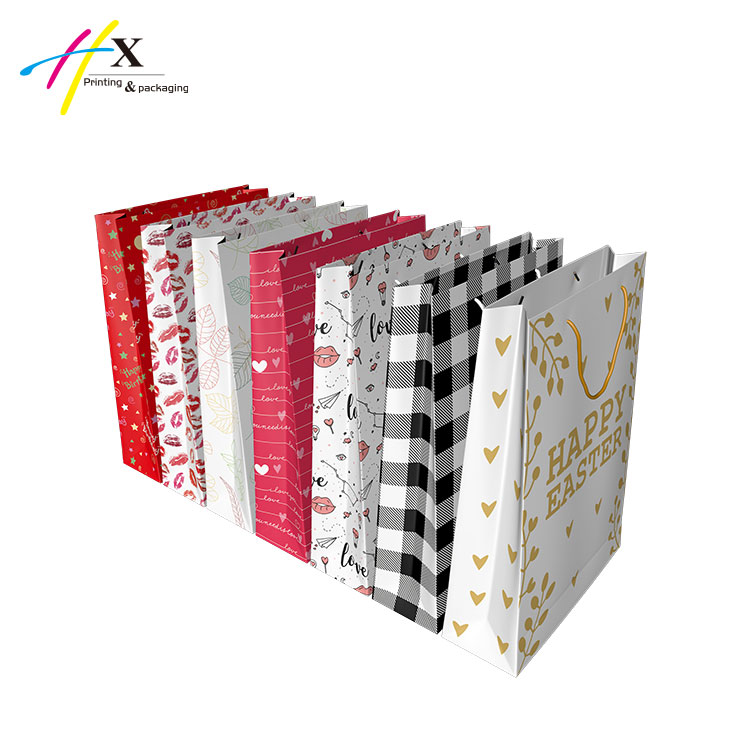

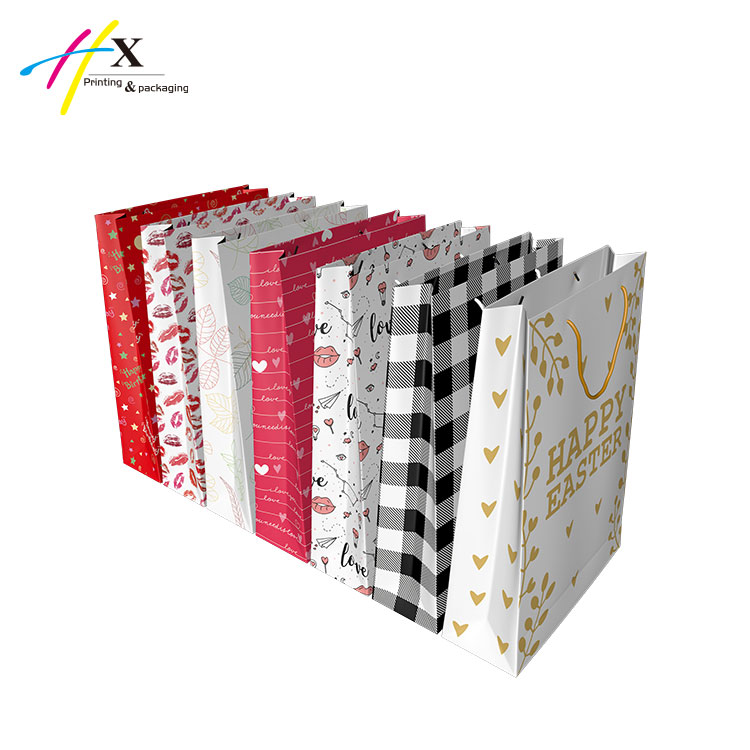

Common Raw Materials For Paper Bag

The white cardboard is strong and smooth, and the printed color is very conspicuous. Paper bags often use 210-300 grams of white cardboard, and most of them are 230 grams of white cardboard. The paper bags printed on white cardboard are full of color and the texture of the paper is very good. It is your first choice for customization.

Coated paper is characterized by very smooth and smooth paper surface, high whiteness, high smoothness and good gloss. It also makes the printed graphics and pictures have a three-dimensional effect, and the commonly used thickness is 128 grams to 300 grams. The printing effect of coated paper is the same as that of white cardboard, and the color is full and bright. Compared with white card paper, the stiffness is not as good as that of white card paper.

Kraft paper also known as natural kraft paper. It has high tensile strength, high toughness, usually brownish yellow in color, high tear strength, bursting and dynamic strength, and is widely used in shopping bags, envelopes, etc. Commonly used kraft paper thickness is 120g-300g. Kraft paper is generally suitable for printing monochrome or two-color manuscripts with uncomplicated colors. Compared with white card paper and white kraft paper, the price of yellow kraft paper is also lower.

Black card paper is a special paper that is black on both sides. The characteristics of black card paper are that the paper is delicate, deep black, strong and thick, with good folding resistance, smooth surface, good stiffness, good tensile strength and high burst resistance. The thickness of commonly used black cardboard is 120g-350g. Because the inside and outside of the black cardboard are black, color patterns cannot be printed, and it is only suitable for hot stamping, hot silver and other processes.